When planning a new driveway, pathway, or patio for your property in Plymouth, one of the most critical considerations is the resin surfacing life span. Resin surfacing is renowned for its durability and aesthetic appeal, but how long does it truly last? In this guide, we will delve into the average lifespan of resin surfacing, the factors that can affect its longevity, and practical tips to ensure your resin surface remains in top condition for years to come.

Understanding the Resin Surfacing Life Span: What to Expect

Resin surfacing is designed to be a long-lasting solution for both residential and commercial properties. On average, you can expect a resin surface to last between 15 to 25 years. However, it’s important to note that this is not a fixed duration—several factors can influence whether your resin surface leans towards the lower or upper end of this lifespan range.

The longevity of resin surfacing largely depends on the quality of the materials used, the expertise involved in the installation process, and the level of maintenance provided. By understanding these factors, homeowners and business owners in Plymouth can make informed decisions that will maximise the life span of their resin surfaces.

Key Factors That Influence the Resin Surfacing Life Span

To gain a deeper understanding of how long resin surfacing can last, it’s essential to consider the various factors that influence its durability. These factors will determine the overall performance and longevity of your resin surface.

1. Installation Quality: The Foundation of Longevity

The quality of the installation process is perhaps the most crucial factor in determining the resin surfacing life span. A well-installed resin surface begins with a properly prepared base. The base layer must be stable, well-compacted, and free from any organic materials that could cause shifting or instability over time.

A professional installation team will ensure that the resin is mixed to the correct consistency and applied evenly across the surface. The curing process is also critical, as it allows the resin to harden and bond with the aggregate, creating a durable and resilient surface. Poor installation practices can lead to a range of issues, including uneven surfaces, inadequate bonding, and premature cracking, all of which can significantly reduce the lifespan of your resin surface.

2. Material Quality: Choosing the Best for Long-Term Durability

The quality of the materials used in the construction of your resin surface plays a significant role in determining how long it will last. High-quality resins and aggregates are essential for creating a strong and durable surface that can withstand the rigours of daily use. In particular, UV-stable resins are crucial in preventing colour fading and degradation due to sun exposure.

Inferior materials, on the other hand, may result in a weaker surface that is more susceptible to damage from traffic, weather conditions, and general wear and tear. Investing in premium materials from the outset can add years to the life of your resin surfacing, making it a cost-effective choice in the long run.

3. Local Weather Conditions: The Plymouth Climate Impact

While resin surfacing is well-suited to the UK climate, local weather conditions in Plymouth can still impact its lifespan. The region’s frequent rain and occasional frosty conditions mean that proper drainage is essential to prevent water from pooling on the surface, which can lead to cracking and other forms of damage.

Moreover, while the UK is not known for extreme sunlight, the cumulative effect of UV exposure over many years can cause resin surfaces to fade if they are not UV-resistant. High-quality resins that incorporate UV stabilisers are recommended to ensure that your surface maintains its appearance and structural integrity over time.

4. Traffic Load: Managing Wear and Tear

The amount and type of traffic your resin surface experiences will also significantly influence its lifespan. Resin surfacing is designed to be durable, but like all materials, it will wear down more quickly if subjected to heavy loads or constant, high-volume traffic.

For driveways that regularly accommodate heavy vehicles such as vans or trucks, or for commercial spaces with high footfall, it may be necessary to use a specific blend of resin that is formulated for enhanced durability. Discussing your needs with a professional installer will help ensure that the right materials are used for your particular situation, thus extending the life span of your resin surface.

Maximising the Resin Surfacing Life Span: Maintenance Tips

While resin surfacing is relatively low-maintenance compared to other paving options, regular upkeep is essential to ensure it remains in excellent condition and lasts as long as possible. Here are some practical tips for extending the life of your resin surface:

1. Routine Cleaning: Keep Your Surface Pristine

One of the simplest yet most effective ways to prolong the resin surfacing life span is through regular cleaning. Over time, debris such as leaves, dirt, and organic material can accumulate on the surface, leading to staining and the growth of algae or moss. Regular brushing with a stiff-bristled broom will help keep the surface clean and free from debris.

For a deeper clean, consider pressure washing the surface. However, it’s important to use a pressure washer on a low to medium setting to avoid damaging the resin. Aim the nozzle at a shallow angle and keep it moving to prevent concentrated water pressure from causing erosion or lifting the resin.

2. Prompt Repairs: Address Issues Early

Even with the best installation and maintenance practices, minor damage can still occur over time. It’s crucial to address any issues as soon as they arise. Small cracks, chips, or areas of discolouration can be repaired relatively easily if caught early, preventing them from developing into more significant problems that could compromise the entire surface.

Regular inspections of your resin surface, particularly after extreme weather events or heavy usage, will help you identify and address any issues before they escalate.

3. Avoid Heavy Loads and Sharp Objects

While resin surfaces are robust, they can still be damaged by excessive weight or sharp objects. To protect your surface, avoid parking heavy vehicles on it for prolonged periods, unless the resin blend used is specifically designed for such loads. Additionally, take care not to drag sharp objects, such as tools or furniture, across the surface, as this can cause scratches and gouges.

4. Preventing and Removing Stains

Resin surfaces are generally resistant to stains, but substances like oil, fuel, or other chemicals can still leave marks if not dealt with promptly. In the event of a spillage, blot up as much of the liquid as possible using absorbent materials such as paper towels or rags. Then, clean the affected area with a mild detergent and water, scrubbing gently with a soft-bristled brush before rinsing thoroughly.

For persistent stains, you may need to use a specialised driveway cleaner designed to break down oil and fuel residues without damaging the resin.

5. Managing Moss and Algae Growth

In the damp and shaded areas of Plymouth, moss and algae can sometimes grow on resin surfaces, particularly if they are not regularly cleaned. To prevent this, ensure that your surface is well-drained and receives regular sunlight where possible. Applying a biodegradable algae and moss remover to affected areas can help keep your surface looking pristine. After application, scrub the area with a stiff-bristled brush and rinse with water.

6. Dealing with Tyre Mark

Tyre marks are another common issue on resin driveways, especially if vehicles turn sharply or brake suddenly on the surface. To remove tyre marks, use a degreasing cleaner or a mixture of warm water and mild detergent. Apply the cleaner to the marks, scrub with a soft-bristled brush, and rinse thoroughly with water.

7. Snow and Ice Removal: Winter Care Tips

During the winter months, it’s important to take care when removing snow and ice from your resin surface. Use a plastic shovel rather than a metal one to avoid scratching the surface. If you need to use a de-icer, choose a salt-based product and apply it sparingly to prevent damage to the resin. Alternatively, sand or cat litter can provide traction without causing harm to the surface.

7. Snow and Ice Removal: Winter Care Tips

Resin Surfacing in Plymouth: A Long-Term Investment

Resin surfacing offers a long-term solution for homeowners and businesses in Plymouth who are looking for a durable, low-maintenance, and aesthetically pleasing surface. With a potential lifespan of up to 25 years, resin surfacing represents a cost-effective investment that enhances the curb appeal and value of your property.

Moreover, resin surfaces are permeable, which means they allow water to drain through, reducing the risk of flooding and helping to manage rainwater runoff effectively—a particularly important feature in a city like Plymouth that experiences frequent rainfall.

Comparing Resin Surfacing to Other Driveway Materials

When choosing a material for your driveway or pathway, it’s important to consider not only the initial cost but also the long-term benefits and maintenance requirements. Here’s how resin surfacing compares to other popular materials:

Resin Surfacing vs. Concrete

Concrete driveways are known for their strength and durability, with a lifespan of 20 to 40 years. However, concrete is prone to cracking, especially in areas with freeze-thaw cycles. Resin surfacing, on the other hand, is more flexible and resistant to cracking, making it a better choice for areas with ground movement. While concrete may last longer, resin surfacing offers better aesthetics, lower maintenance, and improved permeability.

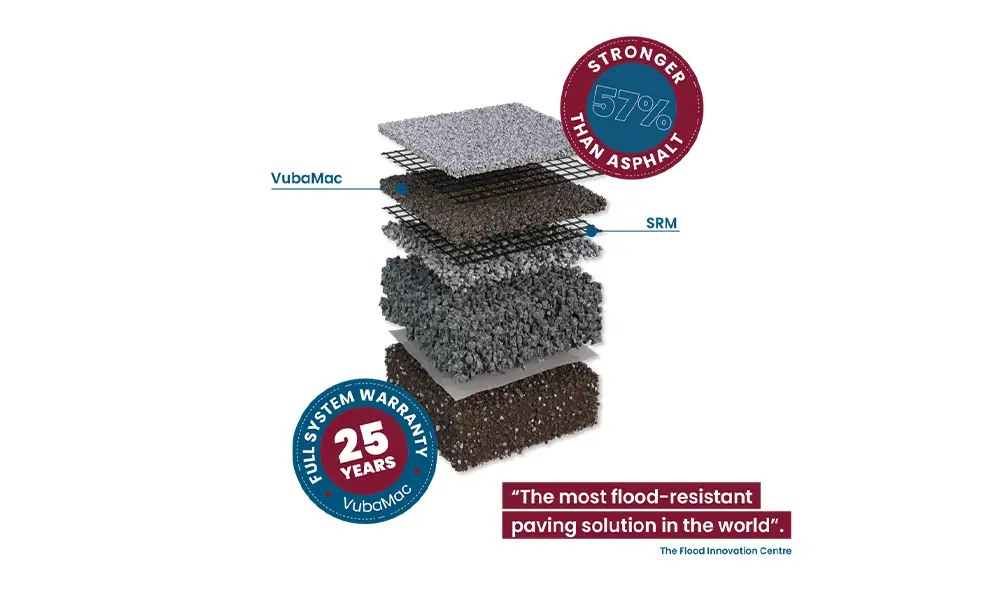

Resin Surfacing vs. Asphalt

Asphalt is another common driveway material, with a lifespan of 15 to 20 years. It is cost-effective and quick to install but can soften in high heat and degrade over time. Resin surfacing, while slightly more expensive initially, offers better resistance to UV rays, less maintenance, and a more attractive finish. Additionally, resin surfaces are permeable, whereas asphalt is not, which can lead to water pooling and potential damage.

Resin Surfacing vs. Block Paving

Block paving is highly durable, with a potential lifespan of 25 to 50 years, and allows for easy repairs as individual blocks can be replaced if damaged. However, block paving requires more maintenance, as weeds can grow between the joints, and the surface may need regular re-sanding. Resin surfacing, while offering slightly less longevity, is virtually weed-free, easier to clean, and provides a seamless, modern appearance.

Conclusion: Enhance Your Property with Long-Lasting Resin Surfacing

In conclusion, resin surfacing is an excellent choice for those looking to combine durability with aesthetic appeal. With proper installation and maintenance, a resin surface can last up to 25 years, providing a beautiful, resilient, and low-maintenance solution for driveways, pathways, and patios.

For homeowners and business owners in Plymouth, investing in resin surfacing not only enhances the visual appeal of your property but also offers practical benefits such as improved drainage, resistance to cracking, and minimal upkeep requirements.

Ready to Transform Your Driveway? Contact Done Right Driveways Today

If you’re considering a resin surface for your property in Plymouth, Done Right Driveways is here to help. Our expert team can guide you through the process, from choosing the right materials to ensuring a flawless installation. Contact us today for a free consultation and discover how our resin surfacing solutions can enhance the beauty, functionality, and value of your property.

01752952163

01752952163